About Us

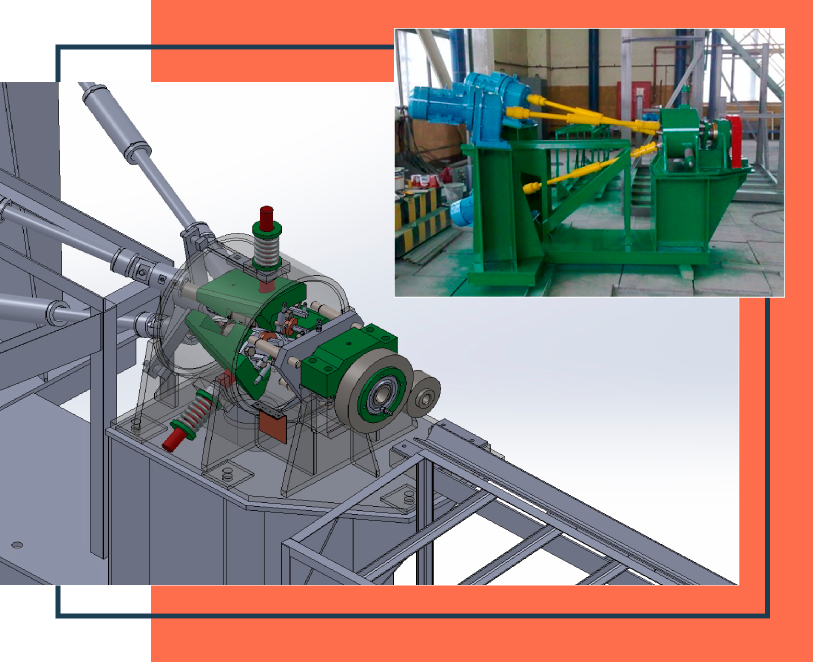

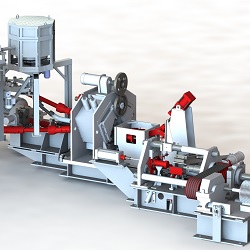

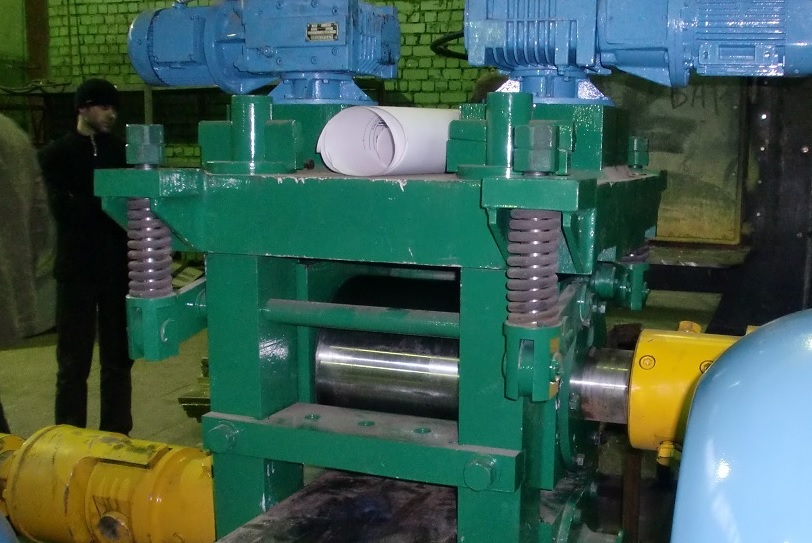

Our company is a leader in the development of screw rolling ministries

“ISTOK” – research, production and implementation small business undertaking was set up in September 1990 and later converted into a closed end joint-stock company “ISTOK ML” Co. in December 1994. Share-holders of the Company – Moscow Institute of steel and alloys and individuals. In 2020, the enterprise was transformed into a joint stock company.

ISTOK ML scope of business:

- arrangement and implementation of comprehensive solutions of innovative technologies, inventions and developments in the realm of ferrous and non-ferrous metallurgy;

- research, pilot developments, design and engineering;

- supply as complete of innovative equipment.