Mini-mills are autonomous machines which provide both independent outlet of the production of goods and broad module configuration according to the dynamics of conjuncture and operational needs.

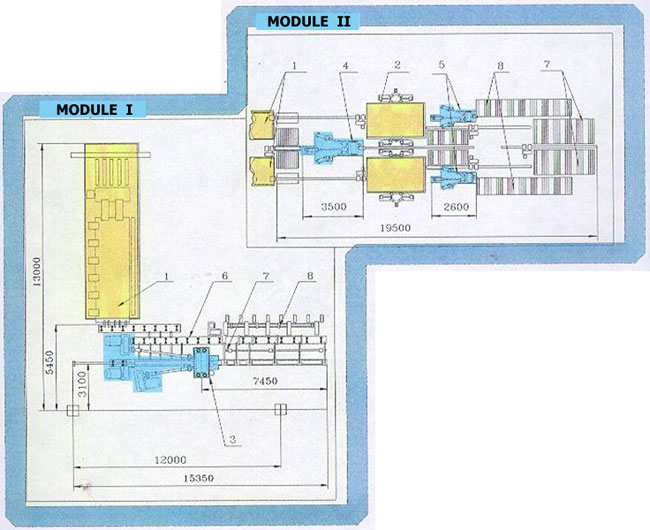

Module I with mill "40-120" is intended for the outlet 3...12 thousand tons per year circular rolling with diameter 40...80 mm from the intermediate product with diameter up to 120mm, including continuously cast. Mass of the equipment is 40 tons, including heating furnaces; occupied industrial areas are about 140 square meters.

Module II being a part of mill "20-45" and two mills "10-30" has the productivity up to 2 t/h of bars with diameter 10...45 mm. Mass of the equipment is 18 tons (basic rolling - 8 tons), occupies area of 150 square meters.

Typical planning and technological conceptions with mini-mills:

- Heating furnace;

- Maintaining furnace;

- Mini-mill "40-120"

- Mini-mill "20-45"

- Mini-mill"10-30"

- Roller conveyer;

- Transmitter;

- Well accumulator.